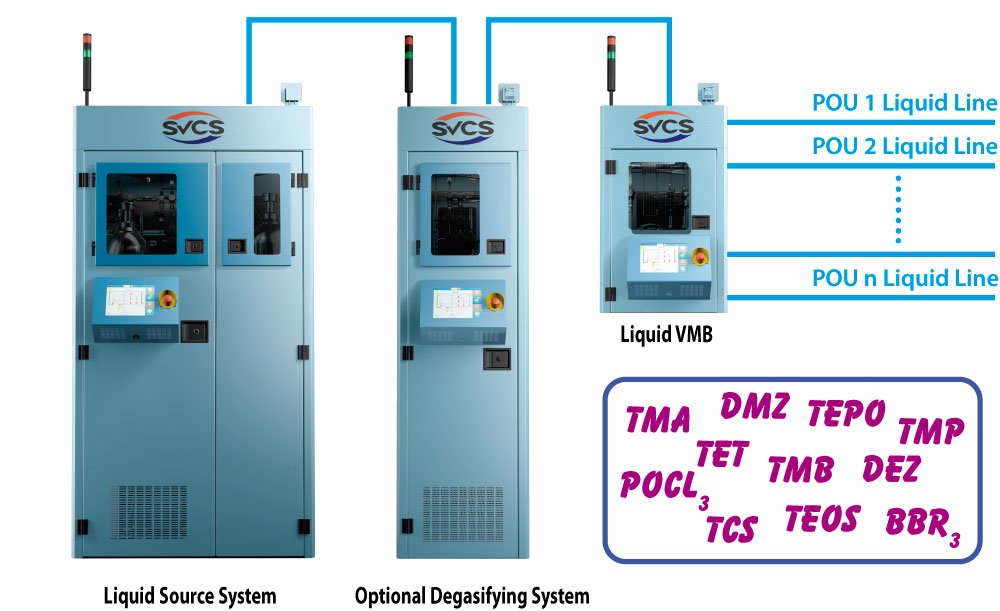

Ultra High Purity Liquid Delivery Systems

High level of technical design

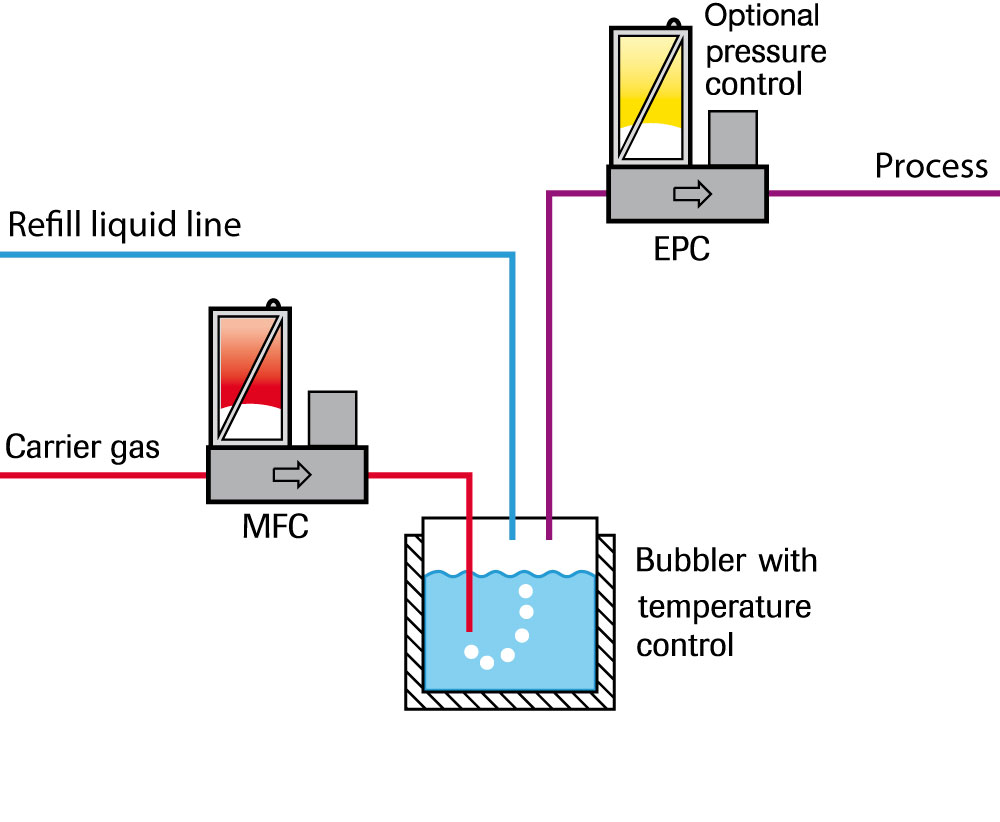

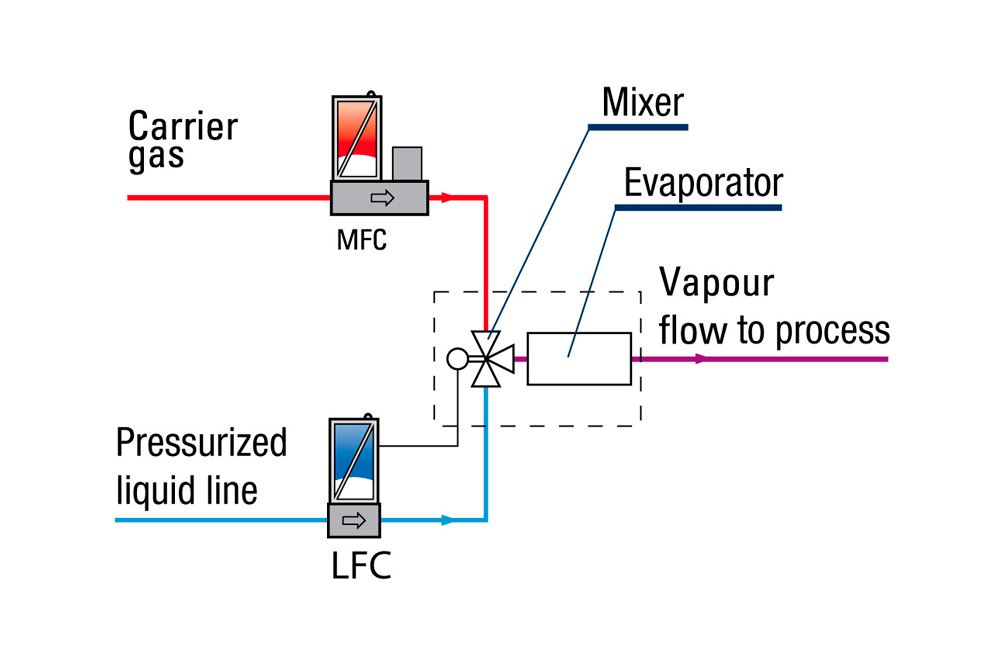

Numerous semiconductor and photovoltaic manufacturing processes use source media available only in liquid phase. Sourcing and distribution systems for a safe and fully automated supply of processes with UHP liquid chemicals are part of our SVDeli product line. The key elements which guarantee safety, reliability and ease of handling have been specially developed for UHP liquids.